Construction of New Loading / Distribution Canopy

On Saturday 02 May, the O’Brien project team at the Barry Callebaut site, undertook a very impressive triple crane lift!

The crane lift was carried out as part of our works on the Banbury chocolate manufacturing plant site, where we are now 29 weeks into a 52 week contract. The new 40 metre span steel frame building extension is for a new loading / distribution Canopy, at the factory.

This is part of 6 phases of work we are carrying out on site as part of upgrading works, within the 6 phases include new access roads, construction of a Weighbridge, the Construction of a new Utility building , an extension to the production building, major internal refurbishment to a further 2 buildings

The works were undertaken on a live manufacturing plant where works continue, with strict additional procedures put in place due to COVID-19.

The above works are following on from our:

Building Alteration and Upgrading Works for New Tank Farm Installation

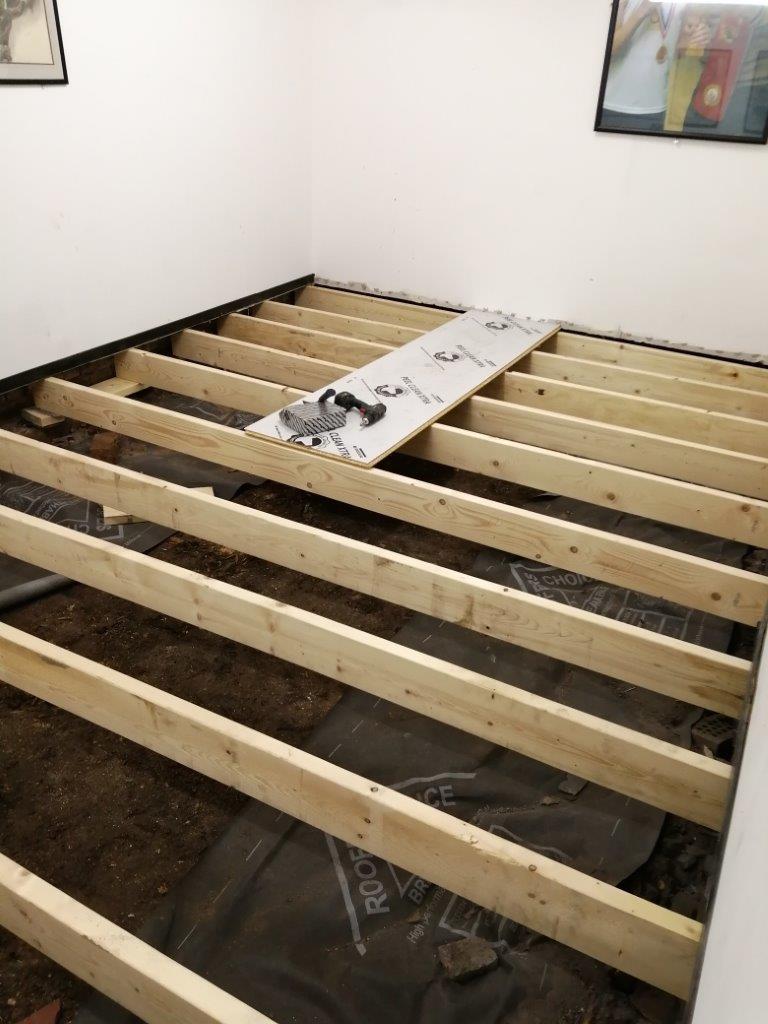

The works which are to allow the client to increase their production by circa 20%, started in November 2019, with major alteration works on the new ‘Tank Farm Building’ completed. The works on this building have been carried out to ensure that the building is ready for the new product tanks to be installed within the building. Our works on this building have included:

- Piling installation in the floor of the building to take the load imposed from the new product tanks to be installed

- Concrete reinstatement – reinstate around piles

- New resin floor installation

- White walling to stop any contamination of the product

- Installation of new steels – these were installed to strengthen the building, and for crane beams

- Painting and decoration of the building

- Brick up old roller shutter doors openings

- Tank Farm Delivery Yard Construction

We have also constructed a new yard around the side and the rear of the ‘Tank Farm Building’ which was previously a landscaped area. The new side access and new yard will allow deliveries to the rear of the building. Our works have included:

- Reduced dig around the side and to the rear

- Muck shift

- Installation of all drainage and ducting for the building

- Install Hauraton channels and kerbs

- Install concrete bases for canopy for the delivery area to the rear

- Stone up

- Concrete bays for the vehicle delivery area.

Other works to the yard area for the ‘Tank Farm’ included the installation of 3 no doc levellers at low level, installation of all new doors and windows for the doc levellers and installation of a building for the janitors, and installation of steel for the canopy.

Building Extension and Construction Works

Our works will be continuing on site until late 2020 with further works including building extension works, internal access roads and construction of a brand new 40m x 13m stand alone Utilities / Energy Centre.

Live Manufacturing Environment

All works are being carried out within a live manufacturing environment with a busy delivery and loading operation on the site. O’Brien have a carefully controlled regime and works phasing to ensure that manufacturing and deliveries on site are uninterrupted. Health and Safety standards are stringent to reflect both O’Brien and Barry Callebaut’s standards.

150 Year Old – World Leading of Manufacturer of High Quality Chocolate and Cocoa Products

Barry Callebaut is the world’s leading manufacturer of high-quality chocolate and cocoa products, and has been dedicated to this business for more than 150 years. The company operates out of more than 40 countries, runs about 60 production facilities, employs a global workforce of more than 12,000 people.

One in Four Chocolate & Cocoa Products Around the World Contain Barry Callebaut Products

With average sales of 2,139,758 tonnes of chocolate and cocoa products (2018/19), their products are present in one out of four of all chocolate and cocoa products consumed around the world.

The works are taking place under a 12 month programme of works.